Optimize an excavation with struts and walers with the DeepEX frame

Bracing, walers and struts should be installed at the elevations shown on the Contractor's plans as soon as practicable. Do not allow the Contractor to advance the excavation or drive steel sheet piling further than the maximum unbraced lengths. See Figures 704-7 and 704-8 for cofferdam bracing using walers and struts.

152UC Waler MGF Excavation Safety Solutions

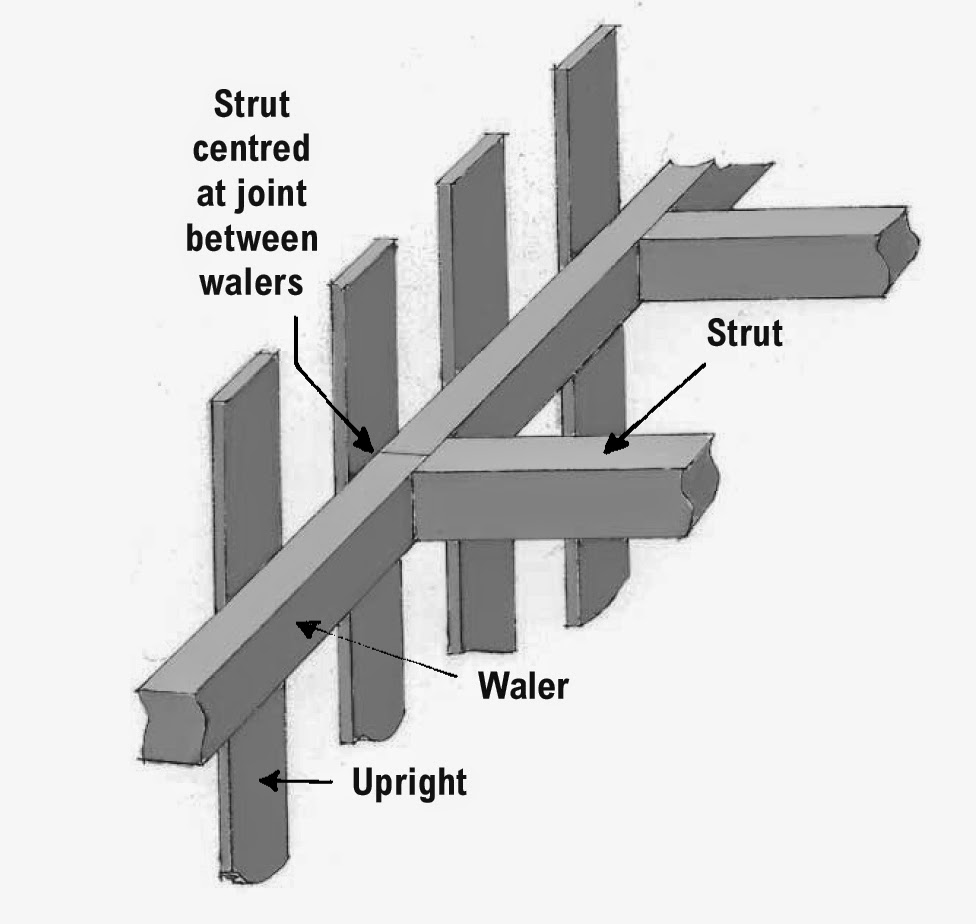

A typical sequence of excavation in cross-lot braced excavations is shown in Figure 1. The struts rest on a series of wale beams that distribute the strut load to the diaphragm wall. Pre-loading ensures a rigid contact between interacting members and is accomplished by inserting a hydraulic jack as each side of an individual pipe strut between.

152 UC Waler & 250kN Hydraulic Strut Safe System of Work MGF YouTube

Walers, rakers and cross-struts are common bracing elements used in most SOE designs. Walers are beams that span across the face of the sheeting disturbing the earth/water pressures to either a raker or cross-strut. Struts are structural elements that transfer the load from an SOE wall to an adjacent parallel structure. Rakers are struts that.

Walers and Struts Trench Sheets Products RMD Kwikform

A large powerboat is moored to a concrete floating dock in a storm. The boat's considerable "sail area," the currents in the marina, and the pulse of waves against the boat are all transmitted through its mooring lines into the floating concrete dock. These forces translate through the dock and are felt as shear forces at the module connections. In our example, the resultant shear force.

BannerStrutting Walls

Walers with hydraulic struts allow end-loading in a 3- or 4-sided application, for pipe repair or valve maintenance. Walers with hydraulic cylinders are designed to be used in a 2-sided application for production work. Walers, used in conjunction with proper sheeting materials, can prove to be a versatile and sure style of shoring protection.

Walers and Struts MGF

RMD Kwikform's range of Walers and Struts are easy to assemble and designed to be used in conjunction with steel sheets for the support of small trenches.. Comprising of five lengths of aluminium walers and two lengths of steel walers with simple pin connections, this easy to assemble hydraulic system is designed to be used in conjunction.

QUALITY CONTROL AND SHE ENGINEERING General Sloping or Shoring

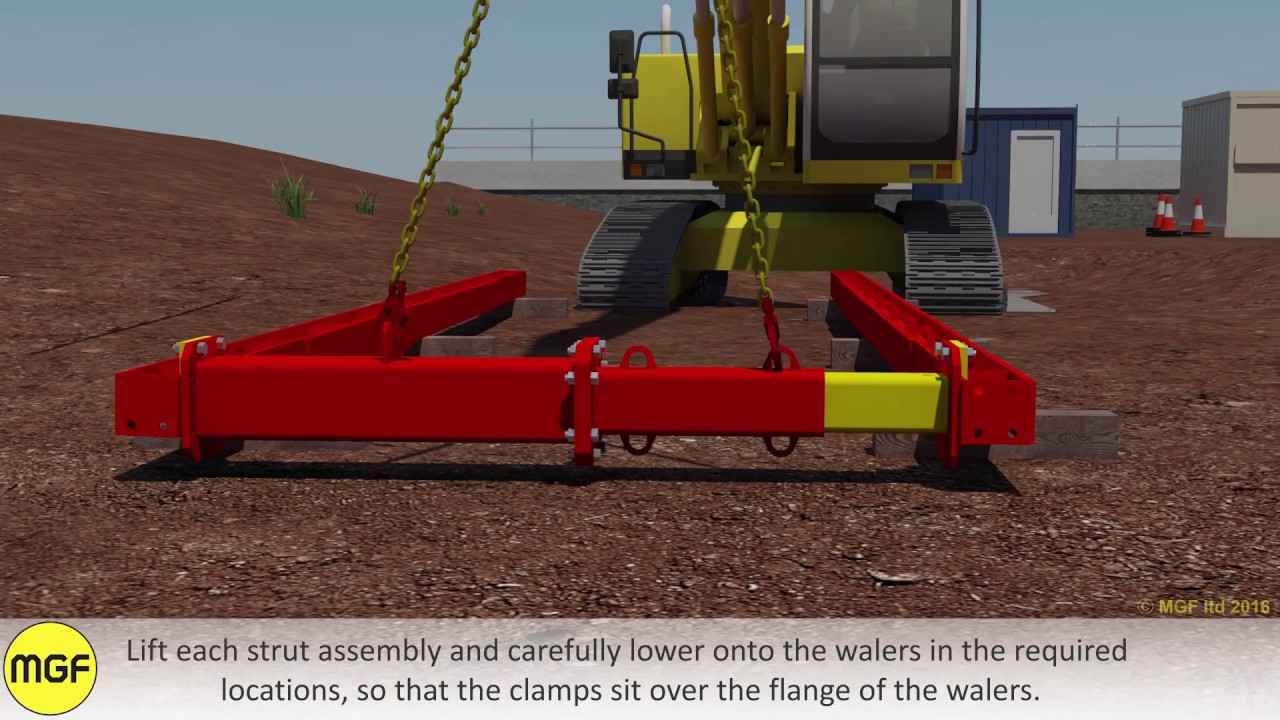

Walers and Struts. A simple to assemble two-sided, hydraulic bracing system designed for use with steel trench sheets to horizontally brace small trenches for the safe installation of utilities. The complete system can support trench widths of 0.6m to 6.0m and is normally installed using an excavator.

Waler Beam Detail The Best Picture Of Beam

This example presents a secant pile wall braced excavation with struts and walers. The excavation model is set with our DeepEX software, and all structural m.

ECD NY Waler / Bracing SOE System

There are no walers and struts to interfere with other construction operations. The limitation is that a 20-foot or less excavation depth is the normal practical limit. Another disadvantage is the piles must penetrate below the excavation at least equal to the height of the excavation. The cantilever is relatively structurally inefficient and.

Hydraulic Waler Frames Typical Installation Methodology YouTube

Endsafe Struts. A simple telescopic strut system for use in conjunction with waler rails and trench sheets. Designed to safely support vertical soil faces at the open ends of trench excavations when it is not possible to safely batter back the ends of the trench to ground level.

Lightweight Waler National Trench Safety UK

Steel Waler System. A heavy duty steel waler system where stronger support is required. Each unit comprises 2 No. steel rails complete with two hydraulic cylinders. These are available in a range of different sizes depending on the trench width. The cylinders fit directly on to the rails and are pressurised by a manually operated hydraulic hand.

Simplified model of strutwaler support system for retaining wall in

During the assembly of walers and struts, there could be a small gap between the strut-waler connection due to fabrication imperfections. How does one decide whether the fillet weld connecting the strut to the waler need to be designed against compression due to possibility of such a small gap? structural-engineering;

MGF Launch New Waler System and 250kN Hydraulic Bracing Strut MGF

RMD Kwikform's range of Struts and Walers are designed and manufactured in accordance with the latest standards EN14653, EN1090 and carry the quality CE Mark. Comprising of 6 different lengths of strut assemblies (types A-F) and 5 different lengths of aluminium walers with simple pin connections, this easy to assemble hydraulic system is.

Introducing our NEW Utility Waler! MGF

Strutting Systems. Whether you require support for permanent or temporary cofferdams, Meever USA has the perfect solution for you. We have a variety of Pipe Struts and Walers that are designed to give strong support to piling walls. In our continuous pursuit of innovation, Meever & Meever is proud to introduce our latest solution in strutting.

Excavation with Struts

Contact Us. 103 Sycamore Street Buffalo, NY 14204. [email protected]. 1 (855) 202-7222.

MGF Launch New Waler System & 250kN Hydraulic Bracing Strut

Simply supported beam; 2. Bending moment and Shear force in the beam; 3. Section modulus of the waler. 4. Design strenth of the waler material. * Lateral soil pressure should be determined per Terzaghi, not Rankine or Coulomb. * You may be using lagging with soldier piles, or you may be using sheet piling with walers.